The art of chocolate tempering is a delicate dance of temperature control, one that hinges on the precise crystallization of cocoa butter. This process is not merely a technical step in chocolate production; it is the very heart of what gives chocolate its signature snap, glossy sheen, and melt-in-the-mouth texture. Without proper tempering, chocolate can appear dull, develop a grainy texture, or fail to release cleanly from molds. The secret lies in understanding how cocoa butter behaves under varying thermal conditions.

Cocoa butter, the natural fat extracted from cocoa beans, is a polymorphic substance. This means it can solidify into multiple crystal forms, each with distinct properties. Of the six known crystalline structures, only one—Form V, or beta crystals—delivers the ideal characteristics for high-quality chocolate. Achieving this requires a meticulous temperature curve that encourages the formation of these stable crystals while suppressing less desirable variants. The journey from molten chaos to crystalline perfection unfolds in three key phases: melting, cooling, and reheating.

When chocolate is first melted, all existing cocoa butter crystals dissolve into a monomorphic liquid state. This complete liquefaction typically occurs around 45-50°C for dark chocolate, slightly lower for milk and white varieties due to their milk fat content. However, simply melting chocolate isn’t enough—the real magic begins during controlled cooling. As temperature drops to 27-28°C, unstable crystal forms (Forms I-IV) begin to emerge. These preliminary structures are weak and disorganized, much like a haphazardly built house of cards. Left unchecked, they would result in soft, crumbly chocolate that melts too easily.

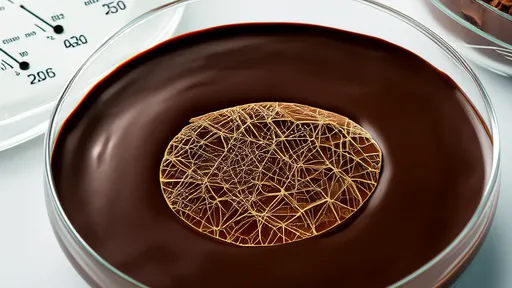

The pivotal moment comes during the final reheating phase, where temperature is gently raised to 31-32°C for dark chocolate. This narrow thermal window serves as a molecular filter: it melts away the unstable crystals while preserving just enough Form V nuclei to seed proper crystallization throughout the chocolate mass. Professional chocolatiers often describe this stage as "working the chocolate," where continuous agitation helps distribute these stable crystals evenly. The result is a network of interlocking beta crystals that align cocoa butter molecules into a tight, uniform matrix.

Modern chocolate production employs various tempering methods, each with advantages for different scales and applications. Traditional table tempering—where chocolate is spread on marble slabs and worked with spatulas—remains favored by artisans for small batches requiring precision. Larger operations often use tempering machines that automate the temperature curve through precisely timed heating and cooling cycles. Some innovative approaches even employ ultrasonic vibration or seed crystals to promote homogeneous nucleation. Regardless of method, success depends on maintaining strict temperature discipline; a fluctuation of just 1°C can shift crystal formation toward inferior structures.

The consequences of improper tempering manifest in several telltale defects. Bloom—those unappetizing white streaks that sometimes appear on chocolate—occurs when unstable crystals revert to more stable forms over time, causing fat molecules to migrate to the surface. Chocolate that refuses to release from molds often suffers from incomplete crystallization, while a soft texture indicates predominance of Form IV crystals. Even environmental factors play a role: high humidity can introduce moisture that interferes with crystal formation, and rapid cooling may trap unwanted crystal types before they can dissolve.

Mastering chocolate tempering requires both scientific understanding and sensory intuition. Experienced chocolatiers learn to read subtle visual and tactile cues—the way chocolate thickens during cooling, the precise moment it begins to set at the edges—as indicators of crystal development. This synergy of chemistry and craftsmanship transforms a temperamental mixture of cocoa solids, sugar, and fat into one of humanity’s most cherished culinary creations. Whether crafting delicate bonbons or industrial chocolate bars, control over cocoa butter crystallization remains the universal language of quality in the chocolate world.

The art of unlocking the full potential of spices lies in a time-honored technique: dry-roasting, crushing, and coaxing out their essential oils. This ancient method, passed down through generations of culinary masters, transforms ordinary spices into aromatic powerhouses that elevate dishes to extraordinary heights. The process may seem simple at first glance, but mastering it requires patience, precision, and an understanding of how heat interacts with different spice varieties.

For many home cooks and professional chefs, peeling and cutting yams can be an unexpectedly unpleasant experience. The vegetable, known for its nutritional benefits and culinary versatility, has a notorious side effect – it can leave your hands unbearably itchy. This common kitchen woe has led to numerous home remedies and old wives' tales, but one surprising solution has emerged from modern technology: the microwave.

The art of making dumplings is a cherished tradition in many cultures, particularly in Chinese cuisine. While the filling often steals the spotlight, the dough wrapper plays an equally crucial role in ensuring the dumplings hold together during cooking. One of the most effective yet underrated techniques for preventing dumpling wrappers from tearing is incorporating egg whites into the dough. This method leverages the science of proteins to create a more resilient and elastic wrapper, capable of withstanding the rigors of boiling or steaming without falling apart.

In kitchens around the world, cooks face a common nemesis when preparing pasta: sticky noodles that clump together into an unappetizing mass. While many swear by the traditional method of rinsing cooked pasta with cold water to prevent sticking, a growing number of culinary experts argue that tossing freshly boiled noodles with olive oil proves far more effective. This technique not only preserves the pasta's ideal texture but also enhances its flavor profile in ways cold water simply cannot match.

Guangdong lychee, a jewel of southern China's fruit basket, has long been celebrated for its succulent flesh and floral aroma. Beyond its irresistible taste, recent research has uncovered a hidden treasure within its vibrant red peel—polyphenols with remarkable antioxidant properties. These compounds are quietly revolutionizing our understanding of how this tropical fruit may contribute to human health far beyond basic nutrition.

The high-altitude coffee farms of Yunnan Province have long been celebrated for producing beans with a distinctive flavor profile. Among the many factors influencing taste, altitude plays a particularly crucial role, especially when it comes to acidity. Unlike the bright, sharp acidity often associated with African coffees, Yunnan’s beans exhibit a more nuanced relationship between elevation and tartness—one that defies simple expectations.

The tender crunch of Zhejiang bamboo shoots has long captivated gourmets and scientists alike, their delicate texture standing as a testament to nature's perfect engineering. While chefs praise their culinary versatility, researchers have uncovered a fascinating cellular secret behind their remarkable freshness – turgor pressure. This biological phenomenon, often overlooked in discussions of vegetable quality, holds the key to understanding why these spring delicacies from China's eastern province maintain their youthful crispness long after harvest.

The Hami melon, a jewel of Xinjiang's agricultural bounty, owes its legendary sweetness to a climatic phenomenon as ancient as the Silk Road itself. Nestled in the arid embrace of China's northwest, this golden-fleshed fruit has thrived for centuries under skies that scorch by day and chill by night. What appears as hardship to most crops becomes the secret alchemy transforming ordinary melons into saccharine masterpieces.

The vast fields of Northeast China, stretching across latitudes from 40°N to 50°N, have long been celebrated as the heartland of soybean production. Among the many factors influencing soybean quality, protein content stands out as a critical metric, not just for nutritional value but also for industrial applications. Recent studies have unveiled a fascinating pattern: the protein content in Northeast soybeans exhibits significant variation along latitudinal gradients. This discovery has sparked renewed interest in understanding how geography shapes the very fabric of this agricultural staple.

The process of homogenization in ice cream mix preparation plays a pivotal role in achieving the desired texture, stability, and mouthfeel of the final product. At the heart of this process lies the principle of fat emulsification, where milk fat globules are broken down into smaller, more uniform particles. This not only enhances the emulsion's stability but also ensures a smoother consistency in the ice cream. The science behind homogenization parameters is both intricate and fascinating, as it directly influences the quality of the end product.

The phenomenon of bread staling has puzzled bakers and food scientists for generations. While most consumers associate staleness with dryness, the underlying mechanisms involve complex interactions between starch retrogradation and water migration within the bread matrix. This intricate dance between moisture and crystalline structures ultimately determines whether your morning toast will delight or disappoint.

The formation of rock sugar crystals is a fascinating interplay of chemistry and physics, where the delicate balance of supersaturation dictates the birth and growth of crystalline structures. At its core, this process hinges on the creation of nucleation sites—tiny clusters of molecules that serve as the foundation for larger crystals. The journey from syrup to shimmering rock sugar is anything but straightforward, and understanding the factors that influence nucleation can unlock greater control over crystal size, clarity, and yield.

The art of chocolate tempering is a delicate dance of temperature control, one that hinges on the precise crystallization of cocoa butter. This process is not merely a technical step in chocolate production; it is the very heart of what gives chocolate its signature snap, glossy sheen, and melt-in-the-mouth texture. Without proper tempering, chocolate can appear dull, develop a grainy texture, or fail to release cleanly from molds. The secret lies in understanding how cocoa butter behaves under varying thermal conditions.

The science behind pickling vegetables has fascinated food chemists and home cooks alike for centuries. While the process may seem straightforward – submerging vegetables in brine – the molecular dance occurring within each cell reveals a complex interplay of chemistry and physics. Recent advances in sodium ion detection techniques have allowed researchers to map the distribution of salt throughout pickled vegetables with unprecedented precision, shedding new light on this ancient preservation method.

The phenomenon of "wine legs" or "tears of wine" has captivated drinkers and scientists alike for centuries. When a glass of wine or spirit is swirled, droplets form on the inside of the glass, creating mesmerizing streaks that slowly trickle back down. This elegant display isn’t just a sign of a good drink—it’s a fascinating interplay of fluid dynamics, surface tension, and evaporation.